|

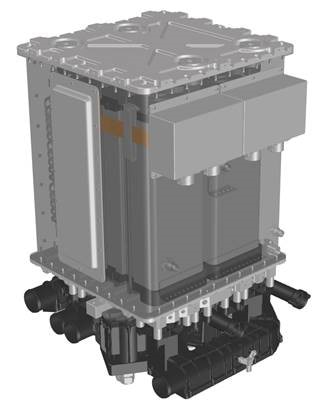

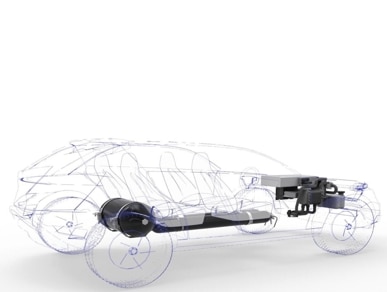

– Subsidiary of ElringKlinger and Plastic Omnium receives series production order covering a projected total volume in the high double-digit million euro range – Contract with AE Driven Solutions for exclusive, multi-year supply of NM5-evo fuel cell stacks from 2022 onward – AE Driven Solutions equips delivery vehicles for urban spaces with fuel cell systems EKPO Fuel Cell Technologies GmbH (EKPO), the joint venture between ElringKlinger (60%) and Plastic Omnium (40%), is continuing to fill up: Aachen-based mobility company AE Driven Solutions GmbH (AEDS) has awarded EKPO an exclusive, multi-year contract to supply fuel cell stacks of the type NM5-evo. The order covers a planned volume in the high double-digit million euro range. The stacks are designed to meet AEDS’s key criteria of performance, durability, and smooth operation and are to be fitted to delivery vehicles as part of the company’s system integration efforts, the aim being to offer environmentally friendly drive technology in urban spaces. Series production of the stacks is scheduled to commence in the first half of 2022. EKPO Fuel Cell technologies press release: |

EKPO Fuel Cell Technologies secures high-volume series production contract for fuel cell stacks