|

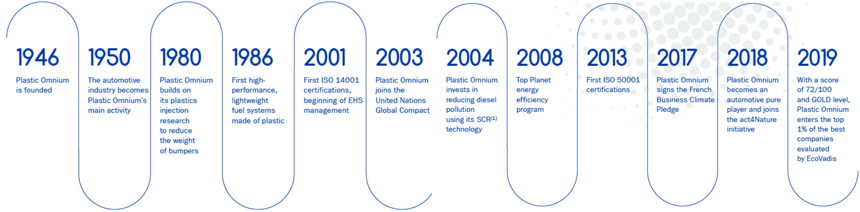

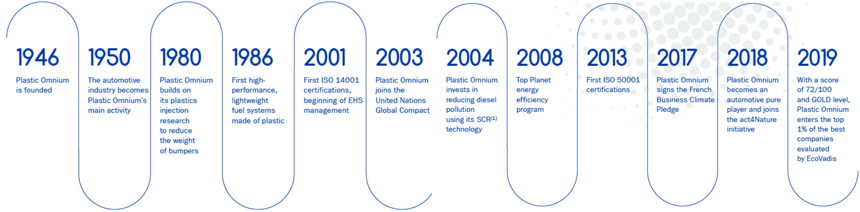

Since 1946, Plastic Omnium has supported the many changes that have taken place in the automotive industry. Lighter cars, emissions reduction , search for cleaner energies, sustainable mobility is historically at the core of our knowhow and at the heart of our business.

Family owned and responsible company, whose growth is built on human and entrepreneurial values Plastic Omnium structures his CSR policy to become a referent partner for his customers in sustainable mobility.

ACT FOR ALL marks a new ambition, in a spirit of continuous improvement of our environmental policy, towards a unique and shared vision of collective commitment.

Today, October 23, 2019 the first ACT FOR ALL day mobilises all of Plastic Omnium world teams around the 3 CSR following pillars:

– Responsible entrepreneurs

– Care for people

– Sustainable production

A history of engagement, concrete initiatives

Today Plastic Omnium launches its new CSR program, ACT FOR ALL !

It marks a new ambition in a spirit of progress and continuous improvement of our safety and environmental approach. A global and unifying program, ACT FOR ALL embodies the commitment of a Responsible Group to sustainable business practices.

The operational objectives are global. In each site, actions will be undertaken to train the teams with ethical obligations, the preservation of the environment, the support of local populations, and health and safety.

In view of the important technological, climate and societal challenges, ACT FOR ALL is in general commitment in the general interest, in order to systematize and measure our actions for everyone, every day.

Our CSR strategy is built on 3 pilars

A GENERAL COMMITMENT TO THE PUBLIC INTEREST

The ACT FOR ALL approach, built on 3 axes, marked out with 10 markers, guides our actions, in the interest of all the stakeholders:

1. Responsible entrepreneurship: Plastic Omnium makes ethics the pillar of its responsible performance. A requirement shared by all its stakeholders.

2. Care for people: A family group, Plastic Omnium strives to provide safe, healthy and equitable working conditions for all its employees around the world, and offers them career and development opportunities.

3. Sustainable production: A responsible industrial company, Plastic Omnium strives to reduce the impact of its factories on the environment by optimizing its processes, from design to manufacturing.

To act and produce in a responsible way and in the respect of all, is part of the Plastic Omnium culture. World leader, the reduction of vehicle emissions is in our DNA, the thread of our research and the pride of our employees.

Read more about ACT FOR ALL

|

To view the video, click here

|