Sustainability Initiatives

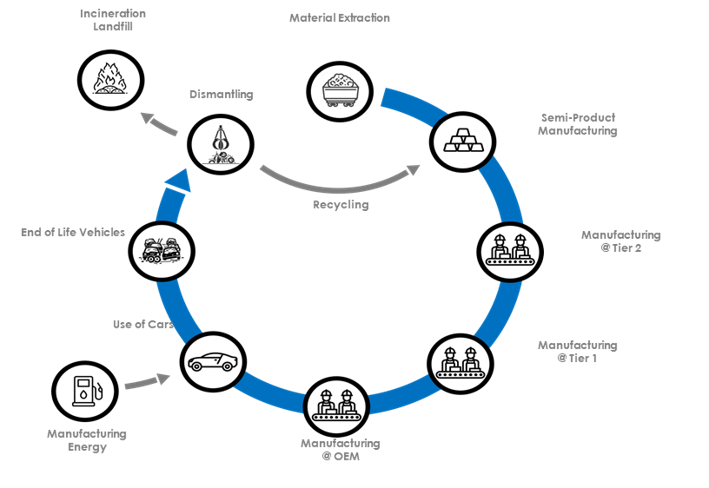

Life Cycle Analysis (LCA)

This is an assessment method aimed at quantifying the environmental impacts of a product or a service. All the potential impacts on the environment are quantified and the consumption of resources is examined, from extraction of raw materials to treatment of waste (“from cradle to grave”).

As a leading supplier to the mobility, we are dedicated to assess the environmental impacts of our products from extraction of the raw materials to the delivery at our customer plant. The LCA process is currently being rolled out to all Business Groups. Stay tuned!

Eco-Design

An ecodesign approach for the smart face product incorporating numerous requierements: fewer materials, optimized logistics, end-of-life of the product, use of materials with less environmental impact, increased recyclability and repairability, implementation of less impactful processes…

The teams compared the LCA of the smart bumper with the results of an ecodesign method for the smart face.

Renault 5 E-Tech electric

OPmobility contribued to the Renault 5 E-Tech electric development for its for its bumpers, wheel arches and rocker panels. Using black parts made from 15% recycled materials, and up to 25% recycled plastic for all parts, OPmobility is dedicated to shaping the future of clean, green mobility.

Bio-sourced materials

OPmobility offers a solution with an intensive use of recycled and biosourced materials in its ecological headlight.

The use of 20% of coffee straw material allows to relieve the projector and improve the energy efficiency, which proves an engagement in favor of sustainability ad innovation.

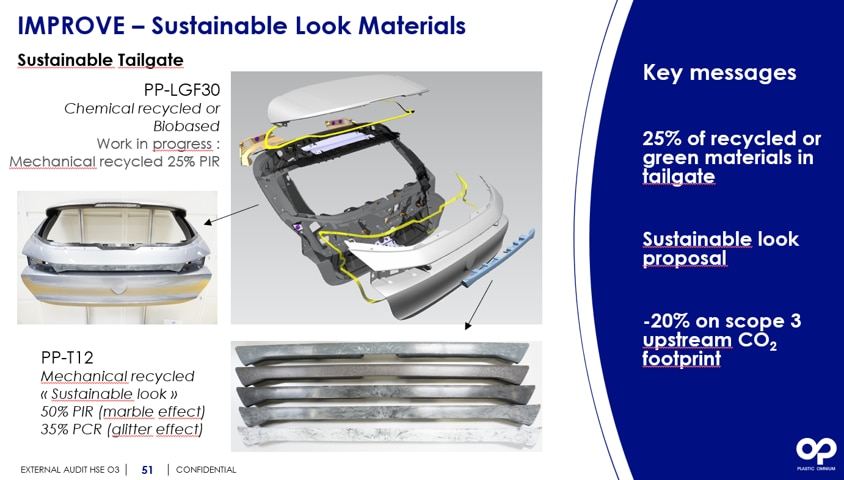

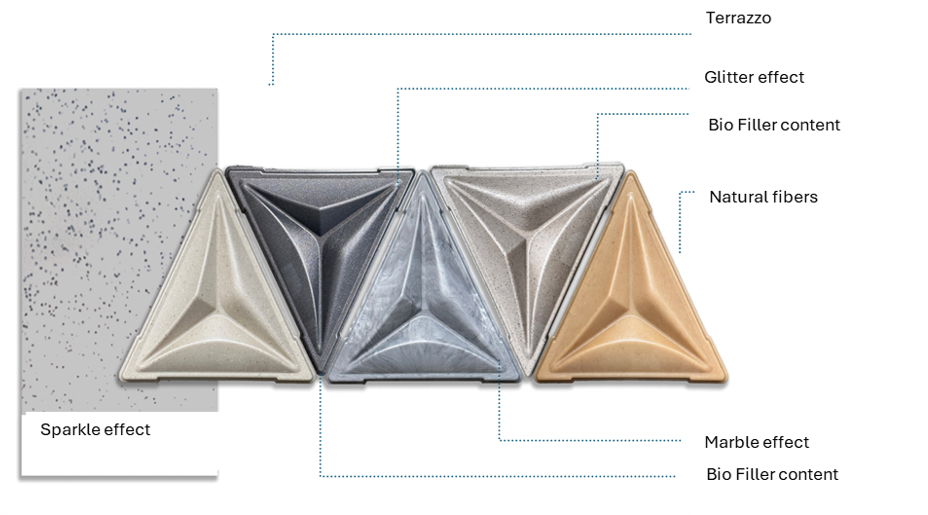

Recycle and bio-sourced materials for sustainable look

We use natural fibers and glitter effects to obtain up to 80% recycled materials in exterior parts, offering unique, long-lasting finishes. This innovation won the “Excellent Product Design Automotive Parts and Accessories” prize at the German Innovation Awards in 2023.